CC and CL Chemical resistance Seal

CC and CL bearing seals

Perfect for use in sea water and other harsh environments!

The combination of bearing shaft seals featuring a PTFE sealing lip and a stainless steel (grade 316) housing make this sealing solution a good option for difficult and extreme conditions. Ideal for use underwater at sea, in dirty environments, for applications with corrosive chemicals or extreme temperatures. There are two types of PTFE seal available and one of them is maintenance-free for the lifetime of the bearing unit – so grease it and forget it!

Key properties

PTFE from Polyfluor has the following properties:

- Dual or triple PTFE sealing lip

- Works under high pressure up to 40 bar

- The ideal choice for high speeds of up to 30 m/s

- For wide temperature range from -79°C up to 260°C

- Excellent chemical resistance

- Suitable for food and pharma applications (FDA-approved)

- Good dry running capability

- Wear-resistant and low friction

- Greatest resistance to fatigue

- Flame resistant – UL94V0

- Antistick properties

- UV-resistant (does not age)

Two types of PTFE seals

These seals are useful for problematic applications such as where temperatures are extreme or chemical resistance is needed. Extreme Bearing supplies two standard types of PTFE lip seals.

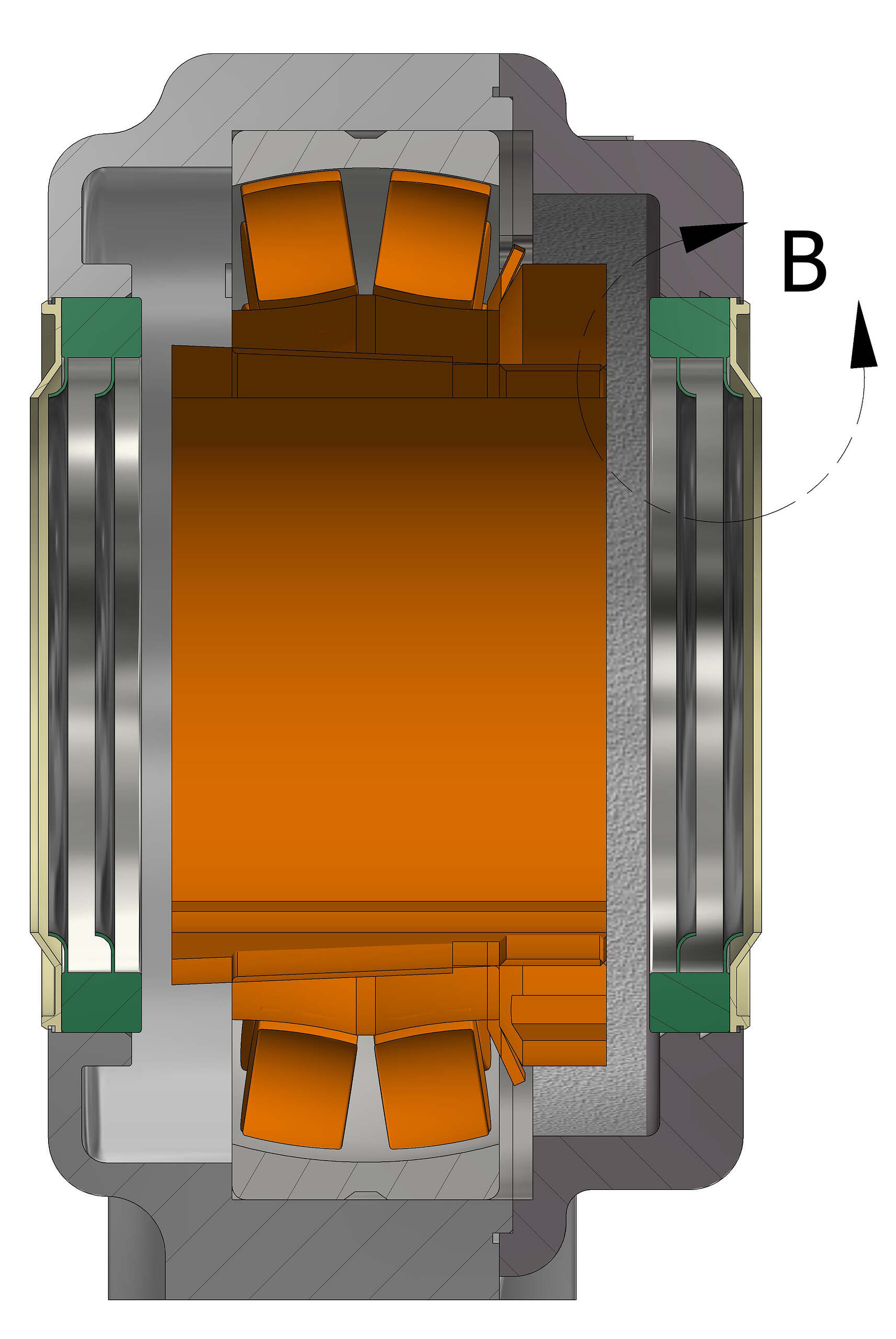

CC flushes dirt away

The CC type is the version with two lips placed on the outside to keep the elements and unwanted contaminants out of the bearing housing. When the housing is filled up with grease, the lips will release the excess grease and discharge the contamination from the sealing surface.

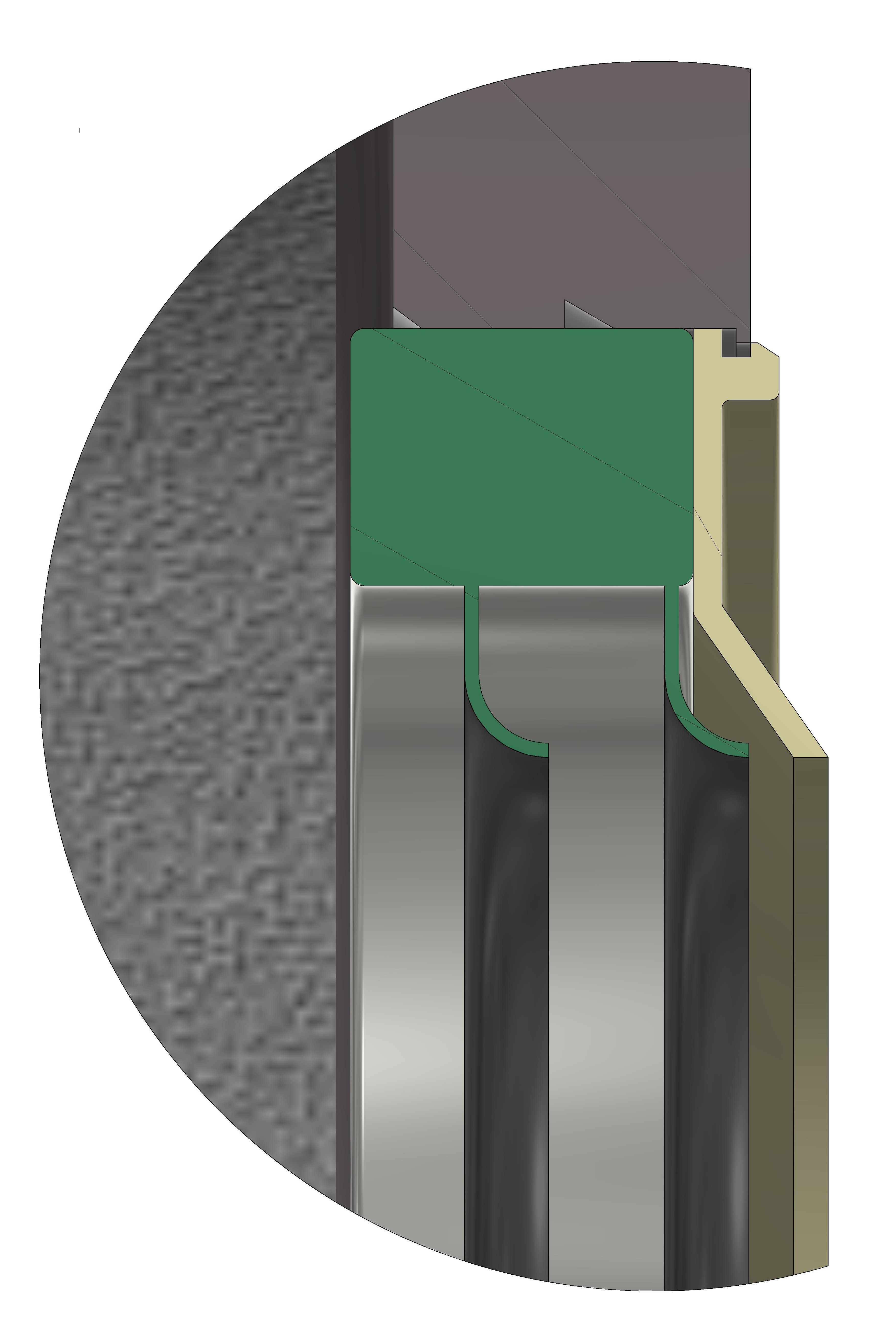

CL is maintenance-free

Where as CL type cannot flush away the contamination from the sealing surface because this seal is equipped with an additional third lip intended to keep the grease inside. The nature of the PTFE material makes it possible for the other two sealing lips to work effectively without lubrication. This makes the CL seal unique for bearing assemblies because it does not need to be regreased and therefore is maintenance-free.

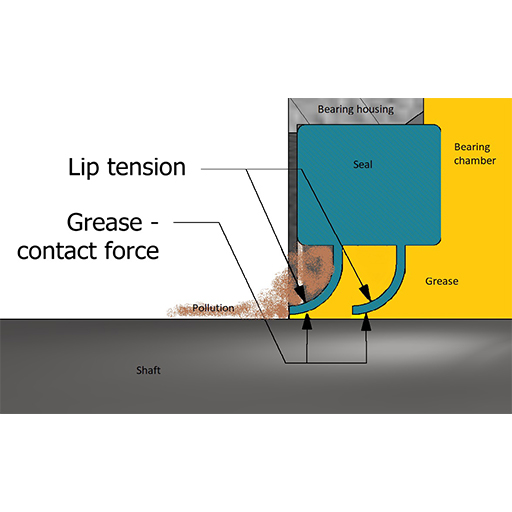

Limited seal lift prevents penetration of dirt

Normal stresses in the grease, due to the high shear rates in the shaft area or in the seal contact area, generate a contact force on the seal lip. This is in addition to the lift generated by elastohydrodynamic lubrication. Because of the overall design of the seal, this lift effect will be limited. Therefore the PTFE lips fit more tightly and with more tension around the shaft. This makes it more difficult for dirt to get under the lip and wear a groove into the shaft.

Double protection

In grease-lubricated Extreme Bearings such as the CC seal, it is not only the small gap between the seal lip and the shaft that provides sealing against contaminants. The grease in between the sealing lips also provides a sealing action.

PTFE makes a poor material against abrasive contamination.

Even though PTFE Seals makes a great material to protect the bearing against lquid, PTFE makes a poor material against abrasive contamination. PTFE material wear out fast if there emerge abrasive material. therefore we recommend to protect these seals with a HS seal protetor ring

To order a protecting ring in fornt of the PTFE Seal just place HS ater the number as example: EXFT050-CCHS-CCHS

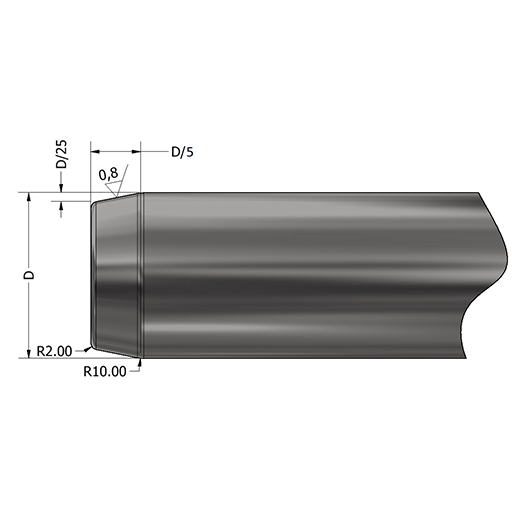

Mounting CC and CL chemical resistant PTFE Seals

You can, with tact, stretch the seal a little.

To prevent shaft wear in contact with the CC and CL seal, we recommend localized hardening of the shaft in the area where the seal is positioned. A minimum hardness of 45 HRC is advised, with a potential increase up to 60 HRC depending on the application conditions and operating environment. This hardening will ensure optimal performance and longevity of both the seal and the shaft.

Chemical resistance PTFE

PTFE is affected by some alkali metals (molten or in solution) and rare fluorinated compounds at high temperatures and/or pressures. Some organic and halogenated solvents are absorbed causing minor dimensional changes but these effects are physical and also reversible.

Note: The chemical resistance of each polymer is mainly determined by the chemical structure of the material and the strength of the weakest link in this specific structure.

Chart codes

R – Resistant

LR – Limited Resistance

NR – Not Recommended

ND – No Data

Waiver

Actual properties may change due to processing method, compound type, extruded dimensions and other variables. It is the user’s responsibility to evaluate and fully test the suitability of the product for their specific application.

| Chemical | Resistance | ||

|---|---|---|---|

| 20°C/68°F | 60°C/140°F | 100°C/212°F | |

| Acetaldehyde | R | R | R |

| Acetic acid (10%) | R | R | R |

| Acetic acid (glac./anh.) | R | R | R |

| Acetic anhydride | R | R | R |

| Aceto-acetic ester | R | R | R |

| Acetone | R | R | R |

| Other ketones | R | R | R |

| Acetonitrile | R | R | R |

| Acetylene | R | R | R |

| Acetyl salicylic acid | R | R | R |

| Acid fumes | R | R | R |

| Alcohols | R | R | R |

| Aliphatic esters | R | R | R |

| Alkyl chlorides | ND | ND | ND |

| Alum | R | R | R |

| Aluminium chloride | R | R | R |

| Aluminium sulphate | R | R | R |

| Ammonia, anhydrous | R | R | R |

| Ammonia, aqueous | R | R | R |

| Ammonium chloride | R | R | R |

| Amyl acetate | R | R | R |

| Aniline | R | R | R |

| Antimony trichloride | ND | ND | ND |

| Aqua regia | R | R | R |

| Aromatic solvents | R | R | R |

| Ascorbic acid | R | R | R |

| Beer | R | R | R |

| Benzaldehyde | R | R | R |

| Benzene | R | R | R |

| Benzoic acid | R | R | R |

| Benzoyl peroxide | R | R | R |

| Boric acid | R | R | R |

| Brines, saturated | R | R | R |

| Bromide (K) solution | R | R | R |

| Bromine | R | R | R |

| Bromine liquid, tech. | R | R | R |

| Bromine water, saturated aqueous | R | R | R |

| Butyl acetate | R | R | R |

| Calcium chloride | R | R | R |

| Carbon disulphide | R | R | R |

| Carbonic acid | R | R | R |

| Carbon tetrachloride | R | R | R |

| Caustic soda & potash | R | R | R |

| Cellulose paint | R | R | R |

| Chlorates of Na, K, Ba | R | R | R |

| Chlorine, dry | R | R | R |

| Chlorine, wet | R | R | R |

| Chlorides of Na, K, Ba | R | R | R |

| Chloroacetic acid | R | R | R |

| Chlorobenzene | R | R | R |

| Chloroform | R | R | R |

| Chlorosulphonic acid | R | R | R |

| Chromic acid (80%) | R | R | R |

| Citric acid | R | R | R |

| Copper salts (most) | R | R | R |

| Cresylic acids (50%) | R | R | R |

| Cyclohexane | R | R | R |

| Detergents, synthetic | R | R | R |

| Emulsifiers, concentrated | R | R | R |

| Ether | R | R | R |

| Fatty acids (>C6) | R | R | R |

| Ferric chloride | R | R | R |

| Ferrous sulphate | R | R | R |

| Fluorinated refrigerants | R | R | R |

| Fluorine, dry | R | R | NR |

| Flourine, wet | ND | ND | ND |

| Fluorosilic acid | ND | ND | ND |

| Formaldehyde (40%) | R | R | R |

| Formic acid | R | R | R |

| Fruit juices | R | R | R |

| Gelatine | R | R | R |

| Glycerine | R | R | R |

| Glycols | R | R | R |

| Glycol, ethylene | R | R | R |

| Glycolic acid | R | R | R |

| Hexamethylene diamine | R | R | R |

| Hexamine | R | R | R |

| Hydrazine | R | R | R |

| Hydrobromic acid (50%) | R | R | R |

| Hydrochloric acid (10%) | R | R | R |

| Hydrochloric acid (conc.) | R | R | R |

| Hydrocyanic acid | R | R | R |

| Hydrofluoric acid (40%) | R | R | R |

| Hydrofluoric acid (75%) | R | R | R |

| Hydrogen peroxide (30%) | R | R | R |

| Hydrogen peroxide (30 – 90%) | R | R | R |

| Hydrogen sulphide | R | R | R |

| Hypochlorites | R | R | R |

| Hypochlorites (Na 12-14%) | R | R | R |

| Iso-butyl-acetate | R | R | R |

| Lactic acid (90%) | R | R | R |

| Lead acetate | R | R | R |

| Lead perchlorate | ND | ND | ND |

| Lime (CaO) | R | R | R |

| Maleic acid | R | R | R |

| Manganate, potassium (K) | R | R | R |

| Meat juices | R | R | R |

| Mercuric chloride | R | R | R |

| Mercury | R | R | R |

| Methanol | R | R | R |

| Methylene chloride | R | R | R |

| Milk products | R | R | R |

| Moist air | R | R | R |

| Molasses | R | R | R |

| Monoethanolamine | R | R | NR |

| Naptha | R | R | R |

| Napthalene | R | R | R |

| Nickel salts | R | R | R |

| Nitrates of Na, K and NH3 | R | R | R |

| Nitric acid (<25%) | R | R | R |

| Nitric acid (50%) | R | R | R |

| Nitric acid (90%) | R | R | R |

| Nitric acid (fuming) | R | R | R |

| Nitrite (Na) | R | R | R |

| Nitrobenzene | R | R | R |

| Oils, diesel | R | R | R |

| Oils, essential | R | R | R |

| Oils, lubricating + aromatic additives | R | R | R |

| Oils, mineral | R | R | R |

| Oils, vegetable and animal | R | R | R |

| Oxalic acid | R | R | R |

| Ozone | R | R | R |

| Paraffin wax | R | R | R |

| Perchloric acid | R | R | R |

| Petroleum spirits | R | R | ND |

| Phenol | R | R | R |

| Phosphoric acid (20%) | R | R | R |

| Phosphoric acid (50%) | R | R | R |

| Phosphoric acid (95%) | R | R | R |

| Phosphorous chlorides | R | R | R |

| Phosphorous pentoxide | ND | ND | ND |

| Phthalic acid | R | R | R |

| Picric acid | R | R | R |

| Pyridine | R | R | R |

| Salicyl aldehyde | R | R | R |

| Sea water | R | R | R |

| Silicic acid | R | R | R |

| Silicone fluids | R | R | R |

| Silver nitrate | R | R | R |

| Sodium carbonate | R | R | R |

| Sodium peroxide | R | R | R |

| Sodium silicate | R | R | R |

| Sodium sulphide | R | R | R |

| Stannic chloride | R | R | R |

| Starch | R | R | R |

| Sugar, syrups & jams | R | R | R |

| Sulphamic acid | ND | ND | ND |

| Sulphates (Na, K, Mg, Ca) | R | R | R |

| Sulphites | R | R | R |

| Sulphonic acids | R | R | R |

| Sulphur | R | R | R |

| Sulphur dioxide, dry | R | R | R |

| Sulphur dioxide, wet | R | R | R |

| Sulphur dioxide (96%) | R | R | R |

| Sulphur trioxide | R | R | R |

| Sulphuric acid (<50%) | R | R | R |

| Sulphuric acid (70%) | R | R | R |

| Sulphuric acid (95%) | R | R | R |

| Sulphuric acid, fuming | R | R | R |

| Sulphur chlorides | R | R | R |

| Tallow | R | R | R |

| Tannic acid (10%) | R | R | R |

| Tartaric acid | R | R | R |

| Trichlorethylene | R | R | R |

| Urea (30%) | R | R | R |

| Vinegar | R | R | R |

| Water, distilled. | R | R | R |

| Water, soft | R | R | R |

| Water, hard | R | R | R |

| Wetting agents (<5%) | R | R | R |

| Yeast | R | R | R |

| Zinc chloride | R | R | R |