Stainless steel bearing housing grease

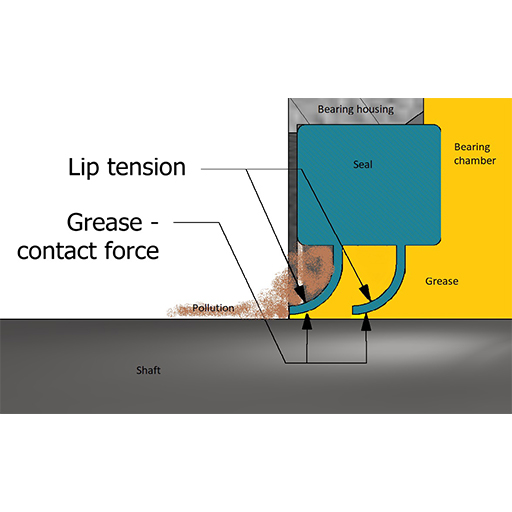

Grease is a great help to seal bearinghousings against contaminants

Grease can be a great help to seal bearinghousings against contaminants. And the gaps between the lips of the centrifugal seal and the stator must be sealed. Because this keeps out dust and water. To improve the bearings life for centrifugal bearing shaft seals, it is recommended to use an automatic lubricator. And to lubricate it regularly. Only a small quantity of grease is necessary when slowly flushed into the bearing cavity. becaus this forces dust and moisture away from the working parts.

What kind of grease should the extreme bearings be lubricated with?

Extreme Bearing units equipped with double row, type-T bearings are supplied without grease.

You can fill these bearing blocks with the grease that is common in your company for spherical roller bearings.

The grease that you put in the bearing, mounted with a E-type single roller bearing, is only intended to make a grease sealing barrier. And this will not influence the working of the bearing. Because the bearing itself is food safe greased for a livetime. And is closed by the 2-rs seals. You can fill these bearing housings with any grease that you have on hand.

Take in consideration that it not will influence the sealing material in the bearing housing.

Quantity of grease requirements or recommendations

The greasing can be done with usual bearing grease. Due to the construction of the CC and CS seals you can’t over grease the bearing.

The idea is that after mounting the housing complete will be filled up with grease until the grease start to escape along the seals

AS and CL are seals pressure-tight. Therefore it is necessary to keep the cap a little bit open while you do the initial greasing so the air traped in the bearing housing can escape.

The amount of grease.

50% to 75% fill For slow speeds when operating speed is less than 50% of the limiting speed of the bearing.

30% to 50% fill For very high speeds when operating speed is less than 50% of the limiting speed of the bearing.

However Extreme Bearing units are most often used on slow moving machines with higher forces such as conveyor belts and sorting machines.

Considering the above and the maximum speeds of the extreme bearings between diameter size 100mm 1000prm and 25mm 6000prm in most situations the grease filling will not be an big issue.

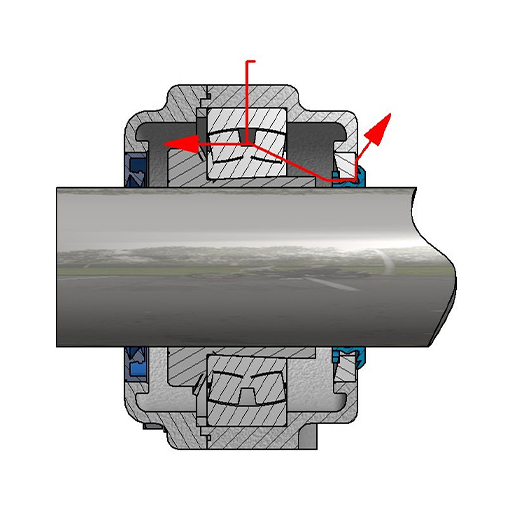

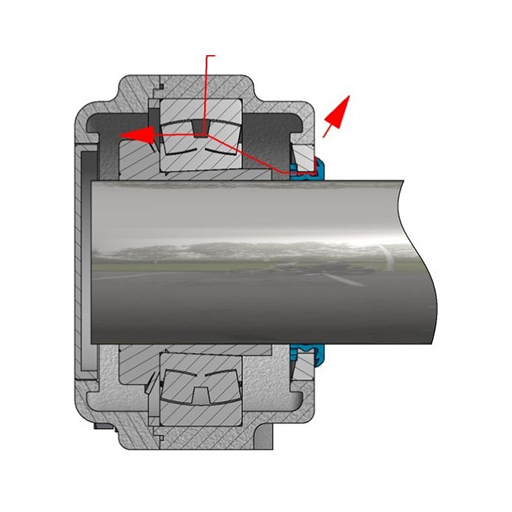

Examples of grease diagrams using AS bearing shaft seals

If the contamination is only on one side of the bearing unit, a seal combination can be chosen that is based on refilling the grease on this side. In this way, the contamination along with the grease shall flow away from the sealing lips. An example of such an assembly, a CS-AS combination, is shown in one of the illustrations with the path of the grease shown by the red arrows.

Central greasing system

The CC type is the version with two lips placed on the outside to keep the elements and unwanted contaminants out of the bearing housing. When the bearing housing is filled up with grease, the lips will release the excess grease and discharge the contamination from the sealing surface. In places where fine abrasive pollution occurs, it is an advantage to install an automatic lubrication system

To improve bearing unit life for it is recommended to use an automatic lubricator or to lubricate regularly. Only a small quantity of grease is necessary when slowly flushed into the bearing cavity to force dust and moisture away from the working parts.

IMPORTANT INFORMATION FOR INITIAL GREASING IF IT IS A PRESSURE-TIGHT BEARING UNIT

In some configurations, the bearing units from Extreme Bearing are bearing shaft seals pressure-tight. Therefore it is necessary to keep the cap a little bit open while you do the initial greasing. Otherwise problems like in the picture shown here can occur.

In addition, whenever it is necessary to add some more grease later, you should always take care not to create overpressure in the housing. The Extreme Bearing units are pressure-tight when used with the following configurations of seals: AS/AS, AS/VK, CL/CL and CL/VK.

Please inform your maintenance crew about this special service operating instruction. It could be helpful to dismount the grease nipples and exchange them with a standard stainless screw, so it will be impossible to make mistakes.